Guide

The Machine Vision Project Checklist

What does a typical machine vision project look like? How long does it take? What do I need to consider to get the right solution?

What does a typical machine vision project look like? How long does it take? What do I need to consider to get the right solution?

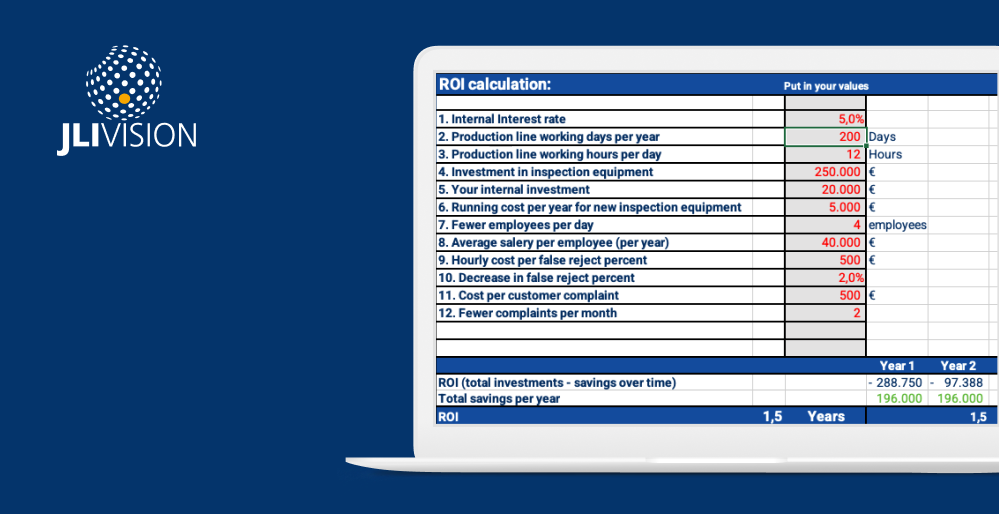

Fill out the Excel sheet and find out what ROI you can expect from your machine vision project.

Get an introduction to the latest trends in machine vision and learn why inspection with machine learning is so effective.

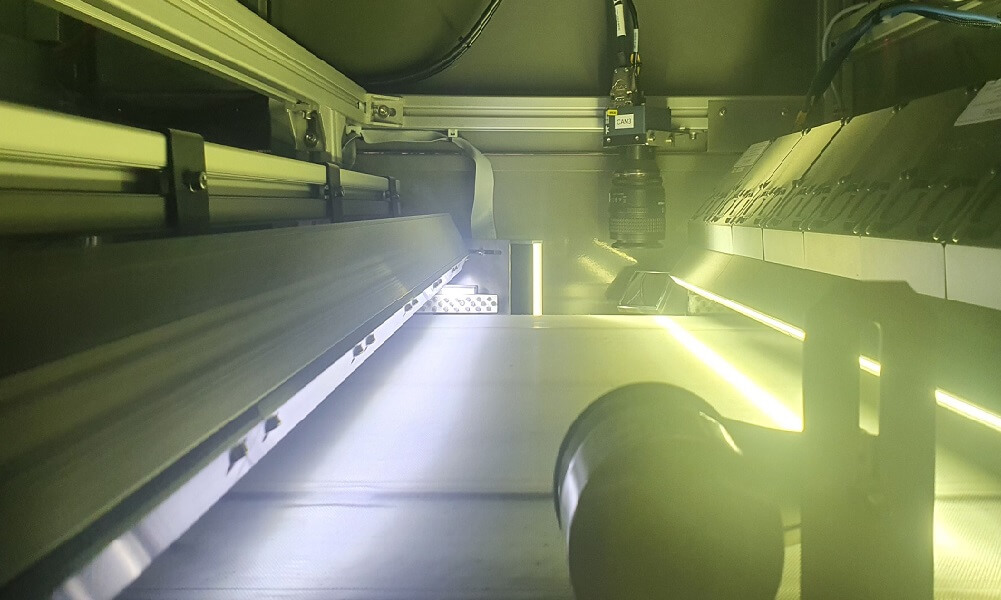

.jpg?width=3000&height=1974&name=Inline%20tube%20inspection%20(1).jpg)

.jpg?width=3000&height=1974&name=Box%20inspection%20(1).jpg)